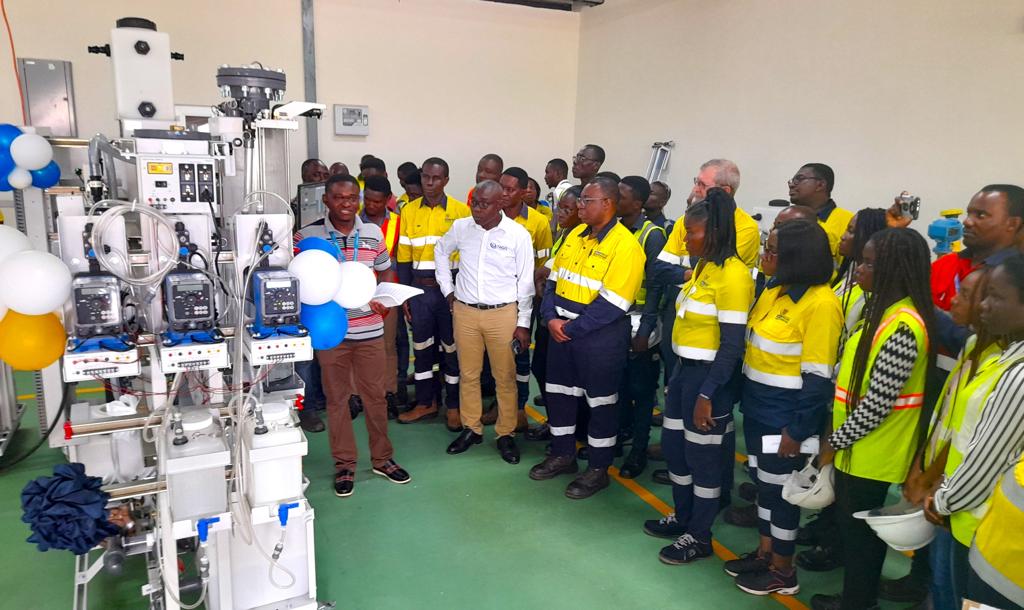

Gold Fields Ghana has announced its plans to enhance efficiency and capacity in gold processing with the acquisition of a state-of-the-art comprehensive instrumentation rig, said to be the first of its kind in Ghana’s mining sector and Africa.

Speaking at the commissioning of the instrumentation processing rig in Tarkwa, Joshua Mortoti, Head of Gold Fields West Africa, expressed that the acquisition of the over €450,000 hi-tech rig marks another milestone for Gold Fields in capacity enhancement.

“This is a major investment that takes the skills development of our employees a notch higher because it adds to our solid technical training modules, equipment and infrastructure. The rig will offer intensive and practical training as it simulates real-world conditions in the process plant in a safe classroom environment. After training with this rig, our instrumentation engineers will be equipped with the technical know-how, which will enhance their competence,“ he said.

Joshua Mortoti further emphasized that the €450,000 hi-tech rig demonstrates Gold Fields’ high regard for employee capacity enhancement over the past decade.

“This is a major investment that takes the skills development of our employees a notch higher because it adds to our solid technical training modules, equipment and infrastructure. The rig will offer intensive and practical training as it simulates real-world conditions in the process plant in a safe classroom environment. After training with this rig, our instrumentation engineers will be equipped with the technical know-how, which will enhance their competence,“ he said.

Joshua Mortoti further emphasized that the €450,000 hi-tech rig demonstrates Gold Fields’ high regard for employee capacity enhancement over the past decade.

“There are a lot of things that we may have to experience or see for the first time or even troubleshoot in the field. Now we have this rig that can help us train and prepare adequately so that when we get into the field, we are familiar with the key instruments in operation. This will help us build stronger capacity and ensure that we deliver to the best of our ability. It is a good instrument, and we must use it well to build our strength and develop our capacity in producing our raw gold,” he said.

Ing Kweku Asmah, CEO of Automation Group Ghana, who facilitated the procurement of the hi-tech rig, expressed that the collaboration resulting in the hi-tech rig will positively impact the mining industry’s productivity.

“As the mining industry significantly influences economies and societies, it becomes imperative to equip its workforce with cutting-edge tools and knowledge. The rig we inaugurate today incorporates state-of-the-art technology, enabling comprehensive training in process instrumentation and automation. It embodies our shared vision of empowering the workforce with the necessary skills. Together, we have opened the doors to a world of possibilities for the mining industry, and we eagerly look forward to witnessing the transformative impact it will have on professionals and the sector as a whole,” he said.

Gold Fields Ghana also stated that the youth from its host communities will have the opportunity to be trained with the rig when the Gold Fields Training School launches the instrumentation apprenticeship program for young people in the host communities at a later date.

Simon Egloff, Business Development Manager of Endress and Hauser, the rig manufacturers described the rig as an “engineering masterpiece” with the latest technology, which would enable process improvements and higher productivity.

“The possibilities which this powerful tool offers makes the Gold Fields’ Tarkwa Mine unique in Ghana and the entire West Africa. Smart sensors using heartbeat technology as a solid base will help move from reactive maintenance to preventive maintenance”.